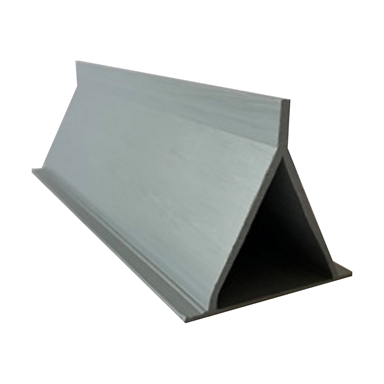

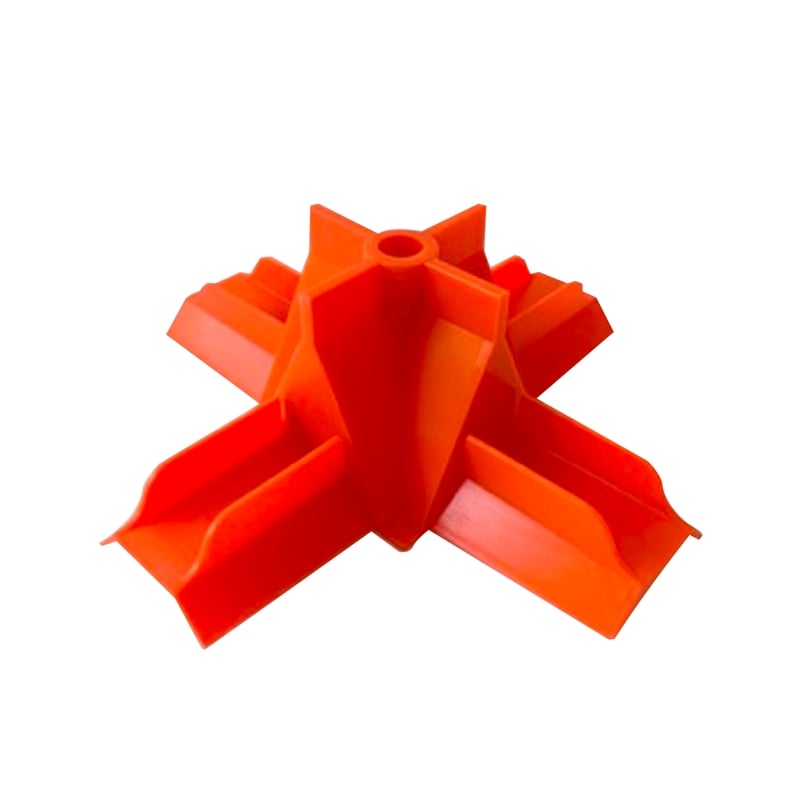

A crack inducer grid is used to induce a closely spaced network of fine cracks throughout the entire area of the slab that do not need to be reflected through applied floor finishes. The ARDEX Concrete Crack Repair & Injection Range uses a high strength, rapid setting two-part system to repair concrete damage from hairline cracks right through to structural repairs. These products are ideal for repairing holes, spalls and cracks in concrete, in internal as well as external situations where heavy duty vehicle traffic is anticipated. Using a tooled joint, where the cement is compressed into a V shape with a trowel and induces a crack whilst wet, is effective in keeping cracks at bay in heavy-duty areas such as long, narrow driveways or internal corners. Specially designed crack inducers can also be used in high-risk areas. Use the largest aggregate concrete size available. Concrete Crack Inducers allow you to put the expansion control crack where you want it, without having to cut and risking damage to cables and pipes. Manufactured from PVC, the Crack Inducers are available in 35mm and 47mm sizes. Both are available in 2.7m lengths, with the 47mm also available in 1.15m lengths when a tighter grid is required. Crack inducers work most effectively in creating early cracking. Unfortunately they can often create the crack prior to sawcutting and then you will have sawn joints with cracks meandering along and across the sawn joint. Often the saw cutter will cut the slab even though it has clearly cracked.

ARTICLE Anya Kussler

If you're about to invest in a driveway or pathway upgrade/installation, start off on the right track by checking out our driveway Q&A guide. We cover all the essentials, from the ideal minimum driveway thickness through to how long concrete will take to set.

Q. Can I pour concrete directly onto the ground?

A: Not a good idea! In fact, it’s really important to prep your surface well before you pour the concrete to prevent it from weakening and cracking. To create an even base and separate the concrete from the ground or clay, use compacted material like GAP20 with fine material (such as GAP7) to finish.

Q How thick do I pour it?

A: Residential driveway (used for light traffic) or path should have a thickness of at least 10cms to minimise the risk of shrinkage and cracking.

Q. What is the difference between concrete and cement?

A: Cement is an ingredient of concrete. Concrete is actually a mixture of sand, gravel or crushed stone aggregates and a paste made up of water and cement.

Q. How can heat and wind cause the concrete to crack, and what can I do about it?

A: Laying concrete in summer, especially a dry hot one, can be challenging because a lack of moisture in the air can cause the concrete to tear. There are numerous ways to prevent cracks from ruining your handiwork:

- Never pour concrete during the hottest time of day.

- Use mesh for driveways (not necessarily for paths) – it helps minimise the width of surface cracks. Position the concrete a third of the way below the surface by placing it on bar chairs with each sheet tied together.

- Dampen the base down properly the night prior to pouring the concrete (that’s if you’re not laying it on polythene (a common plastic used as a base). If you are using polythene, it needs to be a hundred per cent flat, otherwise it can cause the concrete to crack.

- Fog the concrete surface by holding a water blaster a few metres away so a soft mist can settle on it.

- Using a tooled joint, where the cement is compressed into a V shape with a trowel and induces a crack whilst wet, is effective in keeping cracks at bay in heavy-duty areas such as long, narrow driveways or internal corners.

- Specially designed crack inducers can also be used in high-risk areas.

- Use the largest aggregate concrete size available, rather than fine aggregate. Fine aggregate contains more water, which makes it more prone to shrinking and cracking.

Q. How does cold weather affect pouring concrete?

A: Don’t pour concrete in temperatures lower than 5 degrees Celsius as the concrete may freeze and you’ll have trouble setting it, especially when placed on polythene or floor slabs. In colder climates, consider adding a set accelerator to the concrete to speed up the time it takes to harden.

Q. How long do I have to pour the concrete before it sets?

Concrete Slab Crack Control Joints

A: You have one hour (for a truckload worth) before it starts to harden, so it’s crucial that you act quickly (you have about an hour and a half from batching to pouring the concrete). Basically, what happens is that once water is added to cement, it begins to form crystals that interlock with one another and reinforce the concrete. So the quicker you have your concrete in place the stronger it is likely to be once set. If your property is a long distance away from where you get the concrete from, consider adding a set retarder to the mix to delay the hardening process.

Q. Do I need to vibrate the concrete?

A: You sure do – vibrating the concrete in order to release trapped air is essential for it to become strong and durable (except in the case of aggregate or polished concrete where the vibrating can change the look of the finish).

Q. What does cutting concrete mean?

A: Using a circular saw, you literally cut evenly spaced, square or rectangular patterns into the concrete – this will generate joints and prevent shrinkage and ultimately, cracking. It is highly recommended to employ a professional do this job

Q. How long after laying the concrete do I have to wait before I cut it and how deep down do I go?

A: In summer, you need to wait 24 hours before you cut the concrete and in winter 48 hours. You might want to leave exposed aggregate a tad longer; otherwise it can chip. Cut down one-quarter of the thickness of the concrete (i.e. 3cm for a concrete path or driveway that’s 12cm thick).

Q. How do I cure my concrete path or driveway?

A: Concrete becomes hard due to a chemical reaction between cement and water, so without the essential hydration the cement won’t set properly, plus it’ll be weak and look white and dusty. It’s important to keep the concrete consistently wet as soon as possible after pouring it without damaging its surface, for seven consecutive days. Using sprinklers, drip hoses or fogging (see the question on how to prevent cracking) are good options for keeping your driveway and path ‘well hydrated’.

Q. How can I cure my cement if I don’t have access to water?

A: You can spray a curing compound onto the concrete surface of the concrete after you’ve finished laying it. A protective film will develop, which locks the moisture into the concrete.

Q. What are permeable pavers?

Permeable paving is a great option for anyone wanting to put less pressure on their drainage systems. Permeable paving is designed to sustainably reduce rainfall runoff. Firth's durable FlowPave range is designed with driveways in mind and filters both water and pollutants. This driveway option requires minimal maintenance; only the occasional sweep and/or leaf-blowing.

Q. What should I look for in a landscape designer?

A: When seeking out a landscape designer to carry out your driveway/pathway installation, working with a company who can take care of both the design and installation can make a world of difference. Having the same team on board throughout the project will help to significantly keep costs down and the project on schedule. It goes without saying but, before you sign any contracts, make sure you have checked out your designers' past projects and testimonials.

Q. Why Zones?

A: Zones provides an end-to-end project management process which takes care of bespoke designs, builds and maintenance. We can advise you on the best materials for your driveway based on your environment, house style and the amount of traffic it will experience.

Find out more

To learn more about the costs and material options involved in driveway installations, you might like to read: Driveway Costs in NZ. For more information on what Zones has to offer, check out our customer testimonials and completed projects.

Get in touch with Zones to discuss your landscaping project

If you would like to discuss options and ideas for your outdoor landscaping project, please use the enquiry form on this page to provide us with your contact details. We will get in touch with you at a time that suits you to discuss your landscape design and build. If you would like to provide us with more information about your project, we have a more comprehensive enquiry form on our 'Get in touch' page too.

*All information is believed to be true at the time of publishing and is subject to change.

Floor Masters have been fixing concrete surfaces since 2000, and concrete crack repair is a big part of that. Concrete guys have a saying

There are 2 guarantees with a concrete slab, It will go hard andIt will crack. and the other day I heard another line to the saying – if it doesn’t we will replace it.

It’s easy to see that concrete is a fundamental building block in the construction of almost every building and in many landscapes. Concrete is cost effective and durable. It is also worth noting that a crack in concrete does not need to be a big concern, and we can repair cracks in your concrete.

Concrete cracks for many reasons –

Concrete Slab Crack Inducer

Shrinkage is the common – many people do not know that concrete shrinks as it cures, as the water evaporates the particles consolidate. The larger the slab, the greater the shrinkage. This can be evident in two ways – lots of “micro cracking” (very fine cracks) or larger cracks.

Settling cracks – you have just put a heavy slab on the ground and sometimes the ground will compress more in some areas than others. This can often result in the crack being higher on one side than the other, or in extreme cases, changing angles (i.e it sinks at one end).

Substrate movement – in areas with lots of clay in the ground, clay will swell with moisture and shrink when it dries out. These cracks often open and close with different weather cycles.

Subsidence – Where the ground moves or sinks and puts stress on the concrete. Slabs can sink or pull apart.

Understanding concrete crack repair

It is important to understand that a crack in concrete often goes right through the slab, and it can branch out as it goes down. The best concrete crack repair resin is thin, and able to follow the crack in the concrete deeper and make a stronger repair. We use Fast Fix, a hybrid polyurea concrete crack repair resin we import from the USA. Fast Fix is great for crack repair because it is water thin and able to really get down into the crack and “weld” it back together. It is also to follow the branches of the crack and repair the surrounding fractures.

Another bonus of the Fast Fix concrete crack repair resin, is that it cure quickly and we can allow traffic across the floor, or continue with additional floor repairs of coatings in as little as 15 minutes.